The Inside Scoop: A Step-by-Step Guide to the Ultimate Diaper Production Process

When it comes to the manufacturing of diapers, a meticulous and well-orchestrated process is crucial to ensure the quality and comfort of the final product. Here’s a breakdown of the diaper production process from start to finish, giving you a comprehensive understanding of what goes into making these essential baby care items.

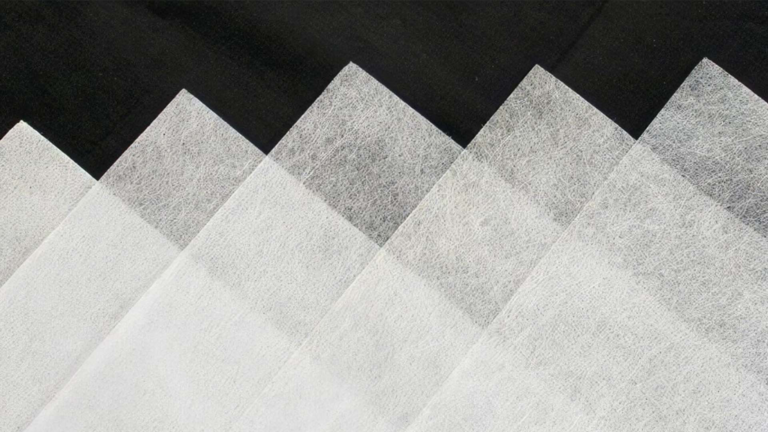

1.Raw Material Sourcing

Key Points: Select materials that are soft, breathable, and hypoallergenic for baby’s comfort.

Hot Air Non-woven Fabric: High loftiness, good elasticity, soft hand feel, strong warmth retention, and excellent breathability and permeability.

Spunbonded Non-woven Fabric: Excellent mechanical properties, good tensile strength, elongation at break, and tear strength. It is thin yet lacks the softness and breathability of hot air non-woven fabric.

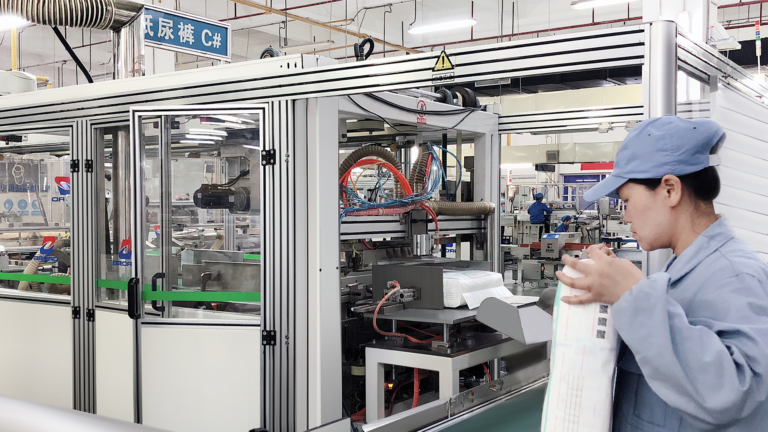

2.Cutting & Shaping

Key Points: Maintain precision in cutting to avoid waste and ensure uniform size and shape. Regularly inspect cutting tools for sharpness and accuracy.

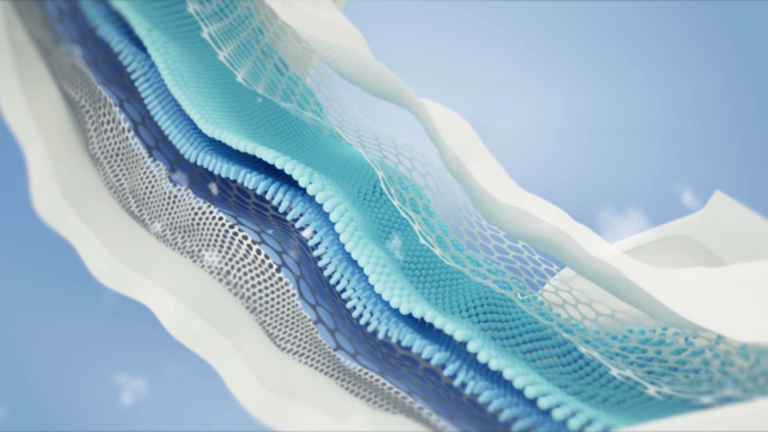

3.Absorbent Core Creation

Key Points: SAP is a key component in diapers, responsible for its absorbency. High-quality SAP ensures maximum absorption and dryness for babies. Ensure SAP is evenly distributed within the absorbent core. Use appropriate compression techniques to maximize water-holding capacity.

4.Assembly

Key Points: Pay attention to alignment of layers during assembly. Ensure edges are securely sealed to prevent leaks. Regularly inspect machinery for smooth operation.

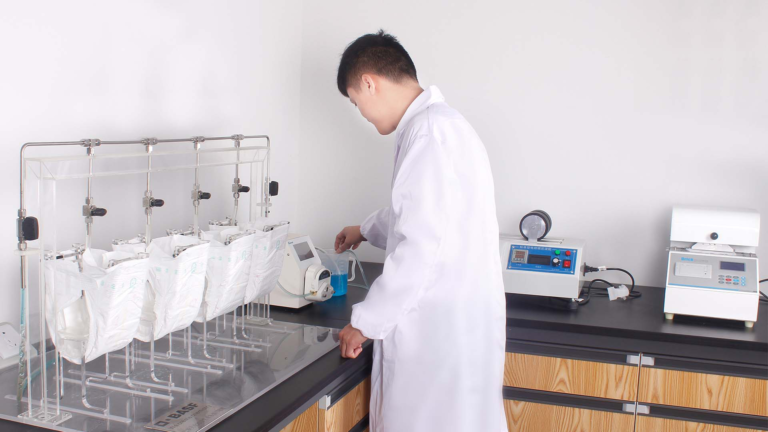

5.Quality Control

Key Points:Perform rigorous testing on random samples to ensure consistency. Test for absorbency, durability, and comfort. Record results for quality assurance.

6.Packaging

Key Points: Use tamper-evident packaging to ensure product integrity. Label packages clearly with size, quantity, and expiration date. Store in a dry, clean environment.

Why MK Health Care is Your Go-To Supplier

Each step in the diaper production process is crucial, and it’s essential to choose a reliable diaper manufacturer and supplier to ensure the highest quality.

MK Health Care stands out as a reliable diaper supplier, offering the following benefits:

- A global leader in eco-friendly diaper brands, committed to providing sustainable solutions for babies.

- A one-stop solution for customized diaper production, packaging, and wholesale services.

- Over 10 years of industry experience, serving clients in more than 50 countries.

- Flagship brand ECO BOOM, recognized for its sustainability initiatives and awarded internationally.

- Products certified by OEKO-TEX OK Bio-base and other international standards for safety and quality.

- A dedicated team ready to assist with tailored sales or product solutions.

If you’re interested in exploring our products and services, don’t hesitate to contact us. Our dedicated team will be happy to assist you in creating a tailored sales or product solution that meets your specific needs. Join us on our journey towards a greener and more sustainable future in baby care.